Did you know the first rope tow in the U.S. was built right here in Vermont in 1934? Powered by a Model-T truck engine, the tow would take skiers to the top of Gilbert’s Hill. Not long after that, the first chairlift was invented in 1936.

And here we are 88 years later and chairlifts are as important as ever to our industry. Here at Sugarbush, we operate 16 public lifts, as well as another 2 in partnership with the Green Mountain Valley School. It takes a lot to run and maintain all these lifts, which are of course spread across two mountains.

There’s no denying that it’s been a tough year for lift operations, not just at Sugarbush but at ski resorts across the country. The reasons are numerous and varied. We recognize, however, that there’s been a lot of chatter about what’s going on with our lifts this year. Recently, I had the chance to sit down with Patrick Konvicka, our VP of Mountain Operations, and Spencer King, our Lift Maintenance Manager in an effort to learn more about our lift situation and shed some light on our lifts this year for all of you.

Staff

As we’ve talked about in past blogs, staffing at Sugarbush, as elsewhere across the ski industry (and many other industries), has been a bit of a struggle. Our lift mechanic department is no exception. Typically we employ a team of about 15 lift mechanics year round. This summer, at one point we were down to a single lift mechanic: Spencer King. Spencer was a 4 year coordinator veteran, now our Lift Maintenance Manager. He has a college background in Ski Area Management, as well as past experience at Targhee and Jay Peak.

Since that low point in the summer, we have continued to hire and train new lift mechanics. We’ve worked quite hard to continue to find ways to make Sugarbush a great place to work and grow a career. Increasing wages (both lift mechanic wages, and separate from that our overall minimum wage, which increased to $15/hr this summer), continuing to expand our benefits, and offering a $1500 signing bonus are all examples of things we’ve done in the past year to continue finding ways to make Sugarbush a great place to work and grow a career.

We’ve been working with local colleges to promote Sugarbush as a mechanical training ground, and provide staff with a livable wage and clear path to gain knowledge and experience within our organization. We have also hired a number of Level II and Level III mechanics within the state certified program. We have made it a priority to get staff in different operations departments sent through the state training program for lift maintenance to add to the overall knowledge and experience of the team including our Director of Operations and Lift Operations Supervisor.

To operate and maintain all our lifts across two mountains miles apart is no easy feat. This team works extremely hard daily. It’s an impressive undertaking and one that our team is very proud of accomplishing. It’s not uncommon for their scheduled 10 hour day to end up being a 12 hour day while still working a minimum of 5 days a week. With staffing levels the way they are, our supervisors can even work 6 to 7 days a week. Plus, this winter has been particularly harsh from a weather standpoint (which I’ll touch on below), and these guys are out driving snowmobiles around through snowstorms, climbing lift towers in subzero temperatures, doing line work in the pouring rain, and everything else your wintry mountain imagination can think of.

Please if you see anyone from our lift maintenance around on your mountain adventures, join me in thanking them for everything they’ve done for us this season. They truly deserve our gratitude.

Maintenance and Capital Plans

It’s important to reiterate that lifts continue to be a high priority for us, both in terms of maintenance and future investment. We’ve been working on finalizing a 10-year master plan, of which new lifts are included in our short/midterm plans for capital looking ahead.

Looking back at the last several years, our most recent new lift projects included replacing the Valley House Double with the Valley House Quad in 2015, which significantly expanded uphill capacity on that side of the mountain while taking some stress off of Super Bravo (not to mention the much welcome loading down below the Valley House Lodge rather than above it like it used to be). In 2017 we replaced both the Village Double and Sunshine Double with Quads, improving our beginner and terrain park experiences. Those were our last three original lifts, and we have now replaced every original lift on the mountain here at least once.

And though we haven’t built new lifts in the last couple years, it doesn’t mean we haven’t still been investing heavily in our lift infrastructure. Lifts are a heavily regulated industry and there is a lot that goes into keeping them safe and operational year over year. Each season there’s a bunch of work we have to do just to meet certain standards. Not only do we always do that, but we typically do additional work exceeding those standards to stay ahead of the curve. This year however, in addition to both of those things, we’ve invested around another $350,000 towards our lifts.

GMX, for example, was having issues with the mechanical pump on the gearbox, causing the lift to shut down. We had to replace this mechanical pump and interestingly enough, they only had two such pumps in the entire country, so our team worked extra hard with the lift manufacturer to get it here and installed as quickly as possible.

On North Ridge, we brought outside contractors in to help us with the electrical, line work, and terminal work needed to get it ready for the season due to our internal staff being stretched thin. As we’ve mentioned before, that lift suffered a pretty significant lightning strike over the summer. We didn’t realize the extent or amount of resources that would be needed to fix the problem. It took us two full months working with contractors and manufacturers to get it running.

Other improvements include replacing the electrical motor in Castlerock and rebuilding the one we have so we would have a spare motor for other lifts. We replaced chairs on Bravo and will be replacing all seat backs on the chairs this summer (which should help with wind). Slide Brook electrical leads, Gate House grips, and a Summit communications line replacement are all other examples of fixes above and beyond what we normally do as well.

What a lot of people don’t realize is the lead time that these projects can take, particularly with the way supply chains have been lately. With most of these projects, we’ve been looking at lead times of 18 months. That’s tricky from a planning perspective, but even more so when something unexpected happens.

I list all of these projects simply as an example of all the unseen dollars and time that goes into keeping lifts spinning each winter. Capital projects like these are essential year over year, but don’t often get talked about much as new lifts since they aren’t as flashy. In addition to what we hope are some bigger and exciting new projects on the horizon, it’s this type of annual maintenance that really makes a difference.

Extreme Weather

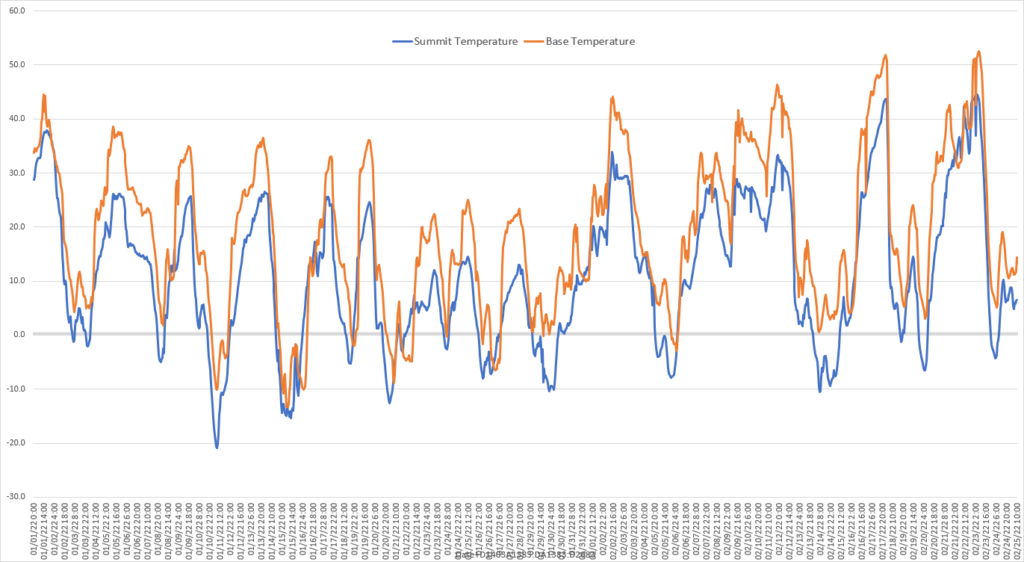

This brings me to the last point about lifts I want to discuss: weather. As likely anyone in the Northeast knows, it has been an absolute rollercoaster of a season. We have seen some incredible temperature swings day over day. And not just in severity but also in quantity. Here’s a chart we pulled of our base and summit temps this season just since January 1st. In the months of January and February alone, we’ve seen major temperature swings from above freezing to below a dozen times. Most of those have been significant drops. I mean just look at the peaks and valleys in this chart! Imagine the stock market looking like that!

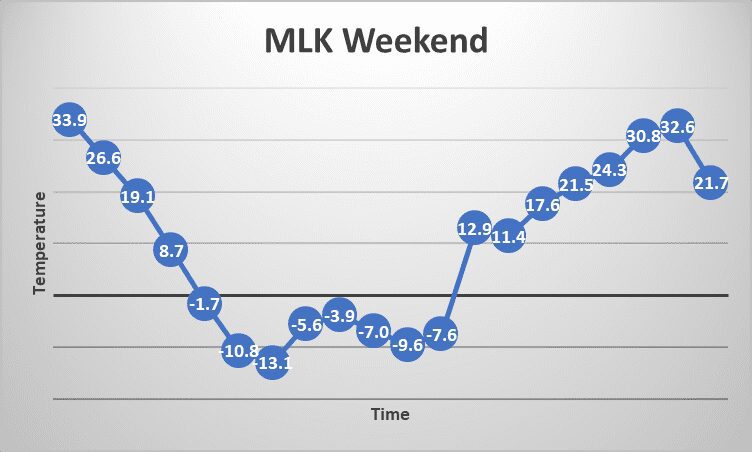

For more of a zoom in, take for example MLK Weekend, which is one of those massive dips in the above chart. Below is a chart of temperature readings at Mt. Ellen’s base every few hours from midnight on Friday, January 14th to midnight on Monday, January 17th. Some of you might recall that GMX had some issues that weekend.

As you can see, we went from above freezing late the night before (and even warmer before that), down more than 40 degrees in the course of a day. Then it ends up doing it again a few days later, which you can start to see on this chart but really see on the bigger chart. Here’s the thing: we’ve never seen anything like this historically, particularly at this frequency.

Now why am I showing you this? Well aside from these weather events obviously having a significant effect on conditions and snow quality, these giant swings can cause serious lift issues. Remember that our lifts span large elevation differences, so even if base temps don’t drop below freezing, the summit station might. These major swings require adjustments to be made from when you turn off the lift at the end of the day (above freezing) to when you start it up in the morning the next day (way below freezing. These issues were something that numerous other resorts have been experiencing too, as the volatile weather has come through this winter.

At first, nobody really knew how to handle this situations. Luckily, the good news here is that the manufacturers, who also hadn’t really seen something like this before, eventually came up with some good solutions for ski resorts. Since then, a lift that had been particularly affected by this, like GMX, has been running much more consistently, even as we continue to see these big temperature fluctuations.

All of this doesn’t even mention the icing events we have had this winter either. These type of circumstances can’t really be prepped for too much, it simply takes crews out there in the morning at each lift chipping away at ice to get the lifts moving and spaced properly. That can again be attributed to these wild temperature fluctuations this year. Then remember it’s all humans doing this work. Our teams were out on the January 11 point you’re seeing on the chart, below -20 degrees (without factoring in wind chill), trying to get things prepped to open.

To Summarize

My hope here is after you’ve read through this blog you have a little more background on everything surrounding lifts this year. We recognize it’s at the forefront of people’s minds right now. Believe us, it’s at the forefront of our minds too. At the end of the day, extreme weather and staffing are the main reasons why lifts have been down a little more this season than we are used to. But also know that lifts continue to be a high priority for us, and we invest annually in keeping these machines functioning safely and efficiently. In the future, we hope to have new capital projects to announce, and included in those plans eventually will be lifts.

We know it’s been a tough year, but we’re confident that our team and knowledge is now in a good place to have a great rest of the reason. I look forward to seeing you all on the mountain.